Scaling lithium-metal electrode manufacturing

Technology

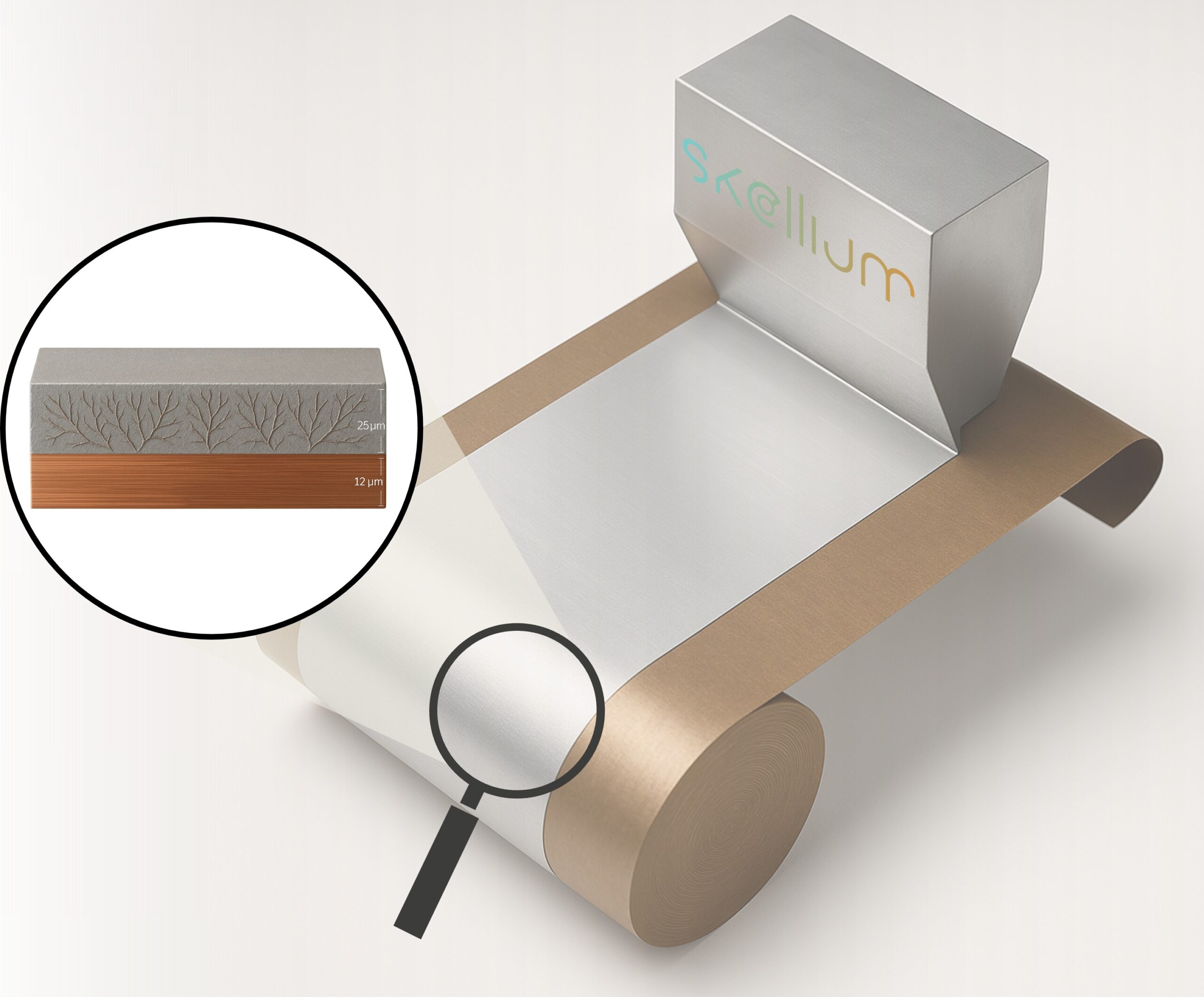

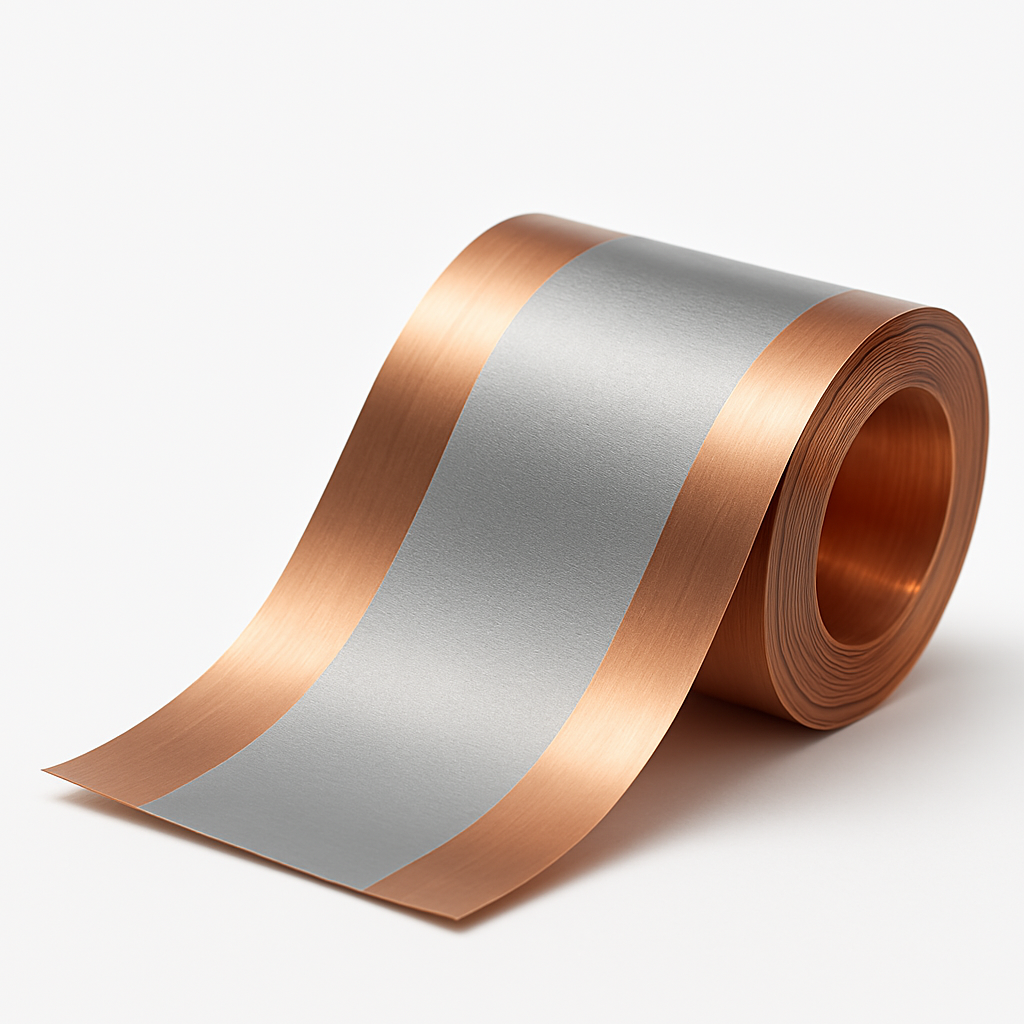

Skellium has developed an innovative liquid coating process to produce thin lithium- metal anodes at industrial scale

Liquid application

Scalable roll-to-roll coating

Ultra-thin coating

Layer thickness according to specification

3d skeleton

Better bonding of materials & dedrite prevention

Scalable production technology

Cost-effective production with standardized process

Interested?

Contact us with your needs and specifications and we send you a sample to test

Team

Combining deep battery expertise, hands-on manufacturing, and big-picture thinking — we’re enabling the future of batteries

The visionary innovator

As the inventor of our core technology, Gerrit is the driving force behind our innovation. With deep expertise in plant and process development and an exceptional understanding of the battery market, he transforms bold ideas into scalable solutions that shape the future of energy storage.

The customer-driven engineer

Formerly head of cell assembly and design, Jonas bridges the gap between technology and market needs. He leads our sales and customer fulfillment, ensuring that every anode solution meets the highest standards of performance and reliability. His hands-on approach ensures that customers are always one step ahead.

The battery chemistry expert

A leading specialist in cell chemistry and solid-state batteries, Junia pushes the boundaries of what’s possible in energy technology. She oversees testing and electrode optimization, ensuring that each cell delivers unmatched efficiency, safety, and longevity.

The strategic accelerator

With a sharp focus on corporate and product strategy, Hendrik drives the company’s growth trajectory. His mission: Accelerate development, scale efficiently, and position the company as a key player in the next generation of battery technology.

News

Latest Updates on Skellium’s Lithium-Metal Innovations, Milestones, and Battery Technology Progress

Skellium Founders Present Lithium-Metal Anode Innovation on the “Geladen” Podcast

Skellium’s founders joined the “Geladen” podcast to discuss our innovative manufacturing process for ultra-thin lithium-metal anodes, where liquid lithium is applied directly onto the copper current collector. In the episode, Gerrit Bockey and Jonas Gorsch explain how this breakthrough lithium-metal electrode technology enables scalable solid-state battery production and why it marks a key step toward next-generation high-energy-density batteries.

Skellium Wins €350K Investment Prize at ChioTech2025 for Lithium-Metal Anode Innovation

Skellium secured the €350K Investment Prize at ChioTech2025 after co-founder Hendrik Minis Pai presented our breakthrough lithium-metal anode manufacturing technology to an expert jury. The win highlights our mission to enable next-generation, high-energy-density and safer solid-state batteries through scalable lithium-metal electrode production — and strengthens our role within the Battery Circle Aachen to close the regional battery value chain.

Skellium Receives Fast Forward Award for Sustainable Lithium-Metal Electrode Innovation

Skellium has been honored with the Fast Forward Award within the RWTH Ideation Program. The recognition underscores our progress in developing sustainable, scalable lithium-metal foil manufacturing for next-generation battery technology. Supported by a strong team and expert coaching, the award highlights our role in Aachen’s growing battery innovation ecosystem and strengthens our momentum for upcoming startup milestones.